1.1 Introduction

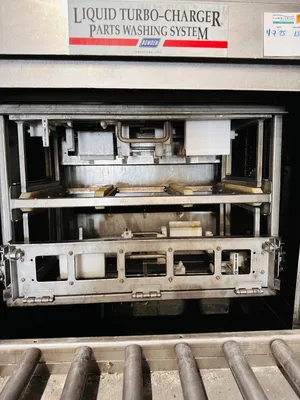

Cabinet Rotating Basket Precision Parts Cleaning System CRB-2-160

Originally built to clean Harley Davidson Transmission Cases. Can be used for many more applications.

CRB-2-160 Model of the Cabinet Rotating Basket line of precision parts washing systems. This model designation defines a system with Cabinet Rotating Basket and 2 tanks; one of which is a 160 gallon wash tank.

1.2 General Description

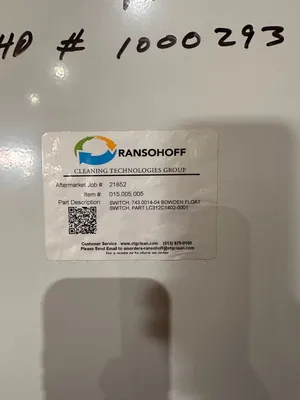

The CRB system is a batch process workcell designed to automatically wash, rinse, and dry delicate parts effectively without risk of damage. The CRB with its Bowden patented Liquid Turbo-Charger™ is especially well suited for cleaning and removing chips from parts with blind holes and other types of difficult-to-clean parts.

System Components

System components for your machine include the following:

1. Loading/rinsing/drying cabinet, in the center of the unit.

2. Custom rotator with fixed lid.

3. Custom roller table.

4. Variable-speed rotator with spring-loaded lock for gate, inside the cabinet, for holding and rotating two custom fixtures.

5. Four custom fixtures to hold transmission cases.

6. Power sprayer, inside the cabinet.

7. Electric convection-heated blower-dryer, behind the cabinet.

8. Hoist, above the rotator, for automatically immersing the parts and lifting them for rinsing and drying.

9. Main Control Panel (MCP) with main disconnect; Allen-Bradley Programmable Controller (PLC), equipped with an Allen-Bradley SLC 5/01 or 5/02 CPU; E-Stop, Start, and Stop buttons.

10. Operator Control Panel, with Start, Stop, Reset, and Emergency-Stop (E-Stop) buttons and an Allen-Bradley PanelView 550™ touch-screen with built-in 7-Day Timer Screen and Tank Heat Screen.

11. Immersion wash tank (Tank 1), directly under the cabinet, with a patented Liquid Turbo-Charger™ that cleans parts with a turbulent flow of proprietary detergent.

12. Rinse-water holding tank (Tank 2), behind the immersion tank, for post-wash spraying.

13. Electric fluid heater in each tank to maintain the fluid at the desired operating temperature.

14. Built-in coalescer behind the immersion tank to remove oil emulsion from the wash fluid.

15. Chip remover and bag-filter unit for the immersion tank.

16. Particle filter for Tank 2 (rinse tank).

17. Oil skimmer for Tank 2 (rinse tank).

18. Automatic refill system for both tanks; Tank 1 auto refill from Tank 2; Tank 2 auto refill from DI source.

1.3 System Operation and Automatic Process Overview

Before the cleaning process can begin, parts are loaded into two custom fixtures which are then loaded into the custom rotator with fixed lid. One fixture is loaded into the bottom slot of the rotator and then secured by the rotator’s spring-loaded lock gate. The load is rotated and the second fixture is loaded into the wash rotator and secured by the other spring-loaded lock gate.

Once the machine’s automatic rotator is loaded with parts, the operator selects the appropriate cleaning programs on the operator interface and activates the START button. The programmable controller takes over, first immersing the parts and rotating them in the wash tank.

While the parts are being washed, the chip remover system automatically removes chips. Chips and fluid from the wash tank flows through the sunken drain valve to the filter system. After being filtered, the wash fluid returns to the wash tank through the return valve and into an internal sparge tube. The sparge tube sweeps chips and debris away from the heater elements, towards the sunken drain valve.

After being washed the parts are then raised into the cabinet for draining, rinse spraying, draining, and then forced-air drying. The rotator automatically returns to the correct load/unload position at the end of the dry cycle.

1.4 System Features

The heart of all Bowden precision cleaning systems is a patented Liquid Turbo-Charger™, which produces turbulent flow in immersion fluid tanks and scrubs all surfaces of even the most complex parts. The turbo-charger keeps oils emulsified while an oil coalescer continually removes the emulsion, and a filter system removes chips and fines.

The combination of the Liquid Turbo-Charger™, coalescer, filters, and proprietary cleaning fluid automatically cleans the cleaning fluid while the cleaning fluid cleans the parts. Parts can be removed from the immersion fluid without being recontaminated, and the useful life of the fluid and pumps are extended as well.

FEATURES & BENEFITS

• Fully automated batch cleaning cycle

• Wash → rinse → force-air dry in one enclosed cabinet

• Patented Liquid Turbo-Charger™ delivers powerful, turbulent immersion cleaning

• Outstanding chip removal — ideal for blind holes & complex internal passages

• Gentle on delicate parts with high-energy cleaning performance

• Continuous filtration, oil removal & fluid conditioning extends bath life

• Allen-Bradley PLC with PanelView touchscreen HMI

• Electric heated tanks with thermostatic control

• Variable-speed rotating fixture system

• Built-in hoist for immersion and lift automation

• Designed for precision manufacturing environments

PROCESS

Load parts → Select program → System automatically:

1. Immerses & rotates in heated wash tank

2. Filters, de-chips, and conditions fluid during operation

3. Raises & drains components

4. High-pressure rinse

5. Forced-air convection dry

Returns to load position automatically

SPECIFICATIONS

• Model: CRB-2-160

• Overall Size: 10’6” F/B × 7’4” S/S × 9’9” H

Wash Tank (Tank 1)

• 160-gallon stainless tank

• (6) × 2.5 kW heaters

• Liquid Turbo-Charger™ A-36 – 7.5 HP | 460V | 3-Phase

• Integrated chip removal & oil coalescer

Rinse Tank (Tank 2)

• 70-gallon stainless tank

• Heated & filtered

• Oil skimmer included

Drying System

• 45 kW electric heat

• 1.5 HP blower convection dryer

Handling & Capacity

• Rotating rack: 300 lb capacity

• Harrington ES-500L hoist | ½-ton rating

Controls & Electrical

• Allen-Bradley SLC 5/01 or 5/02 PLC

• PanelView 550 HMI

• 200 Amp disconnect

Includes chip filtration, oil separation, automatic tank refill system, and Torit DMC-B mist collector.

APPLICATIONS

Perfect for:

• Transmission & drivetrain components

• Large Precision machined parts

• Aerospace & defense parts

• Automotive & powertrain manufacturing

• Aluminum & cast parts

• Medical / clean manufacturing prep

We use cookies to improve your experience. Privacy Policy.