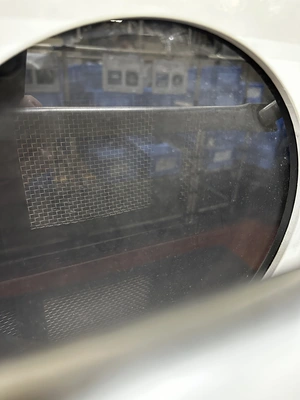

The LeanJet RB-2 immersion cleaning system processes two (2) baskets of parts per cycle, up to twenty (20) baskets per hour. The RB-2 carriage can be easily modified to accommodate much larger parts. Designed to fit into your work cell area or a smaller production environment, the Lean-Jet RB-2 immersion cleaning systems clean using our patented washing and rinsing process of agitation, spray impingement, rotation, hydraulic purging through immersion, and heated blow-off drying. Our patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages. In addition, the RB-2 parts washer is designed to be equipped with ultrasonics if needed. Totally enclosed self-ventilating process - operator is not exposed to vapors or mists found in other cleaning processes.

Wash

Rinse

Blow-Off

Ultrasonics

Designed to hold (2) Kadon baskets, carriage insert can be removed for a 15x15x24 work envelope

Options purchased:

Pro Sep Oil Removal System

Three Color Stack Light

Chip Basket (wash only)

Exhaust Fan = 12 Stainless Tube Axial

Manifold Drains

Sump Pump Tank with Pump - Powered from Machine

Carriage Insert for 2 Kadon Style Baskets

2 Kadon Style Processing Baskets

Allen Bradley Controls HMI&PLC Included

Ultrasonics

Utilities:

Fresh Water Supply 3/4" NPT coupling Tank Fill

Electric Power 460/3/60

Compressed Air 3/8" PT 30GPM/70FT

Sump Pump Tank Discharge 2" NPT 30 GPM/70Ft

Exhaust 12" Pipe Flange

Pro Sep Drain 1-1/2" NPT Capped

We use cookies to improve your experience. Privacy Policy.